API Standard Oilfield Integral Spiral Blade Drilling Stabilizer/Near Bit and Drill String Type Stabilizer

Integral blade stabilizer is an important tool in the drilling engineering to control the well deviation.It can stabilize the drilling tools in the drilling process of oil ,gas and geological exploration. It can increase the bit life,drilling speed and well bore quality. There are two kinds of integral stabilizers:spiral integral blade stabilizer and straight integral blade stabilizer.

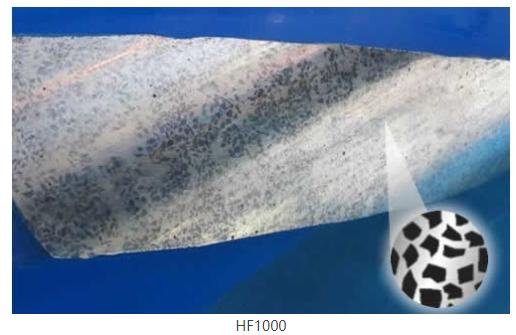

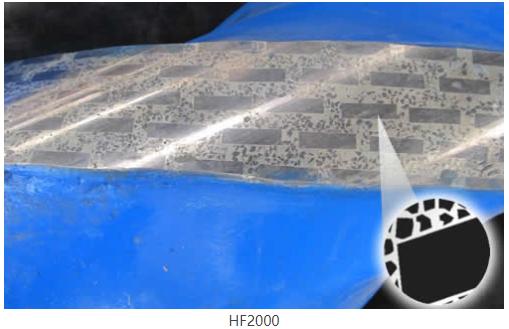

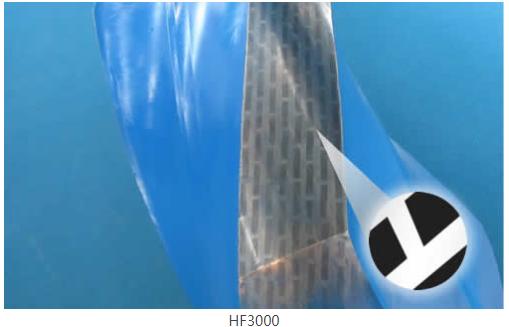

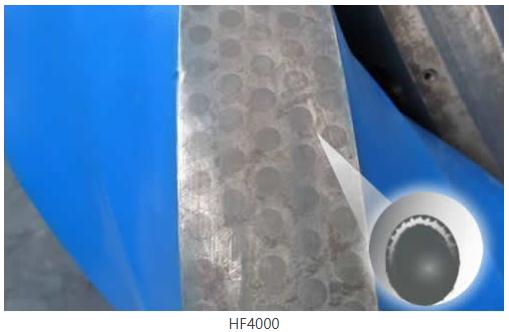

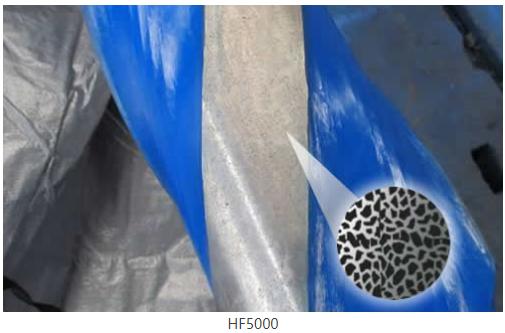

Hard facing types of stabilizers

Crushed tungsten carbide held in a nickel bronze matrix. The 3mm grain size ensures greater concentration of carbide which is ideal for soft formation drilling.

Trapezoidal tungsten carbide inserts held in a sintered carbide nickel bronze matrix. This will give a greater depth of carbide coverage – ideal for high deviation drilling in abrasive formations.

Tungsten carbide inserts set in a powder spray deposit ideal for abrasive formations. 97% bonding guaranteed, certified by ultrasonic report. Recommended for non-magnetic stabilizers.

Tungsten carbide inserts (button type). The inserts have been developed to allow cold insertion and maintain close fit. A greater concentration of inserts on the bottom third of the blade and leading edge will increase surface contact to reduce wear in highly abrasive formations.

This oxy-acetylene process applies tough molten carbide particles of varying sizes held in a nickel chrome matrix which provides excellent bonding properties and greater surface wear characteristics are achieved. Surface hardness levels over 40 HRC. Ideal for GEO-THERMAL applications over 350°.

Specification

Model | Hole size OD mm(inch) | Fishing Neck OD mm(inch) | Upper Conn. | Lower Conn. | ID mm(inch) | Fishing Neck Length mm(inch) | Blade Axial Width mm(inch) | Blade Length mm(inch) | Remark |

LX98 | 98.4(3 7/8) | 79.4(3 1/8) | NC23 | NC23 | 31.8(1 1/4) | 240(9 29/64) | 34(1 1/32) | 240(9 29/64) | String |

LX149 | 149.2(5 7/8) | 120.7(4 3/4) | NC38 | NC38 | 50.8(2) | 600(23 5/8) | 50(1 31/32) | 350(13 25/32) | String |

LX149-NB | 3 1/2REG | Near Bit | |||||||

LX216 | 215.9(8 1/2) | 165.1(6 1/2) | NC50 | NC50 | 57.2(2 1/4) | 600(23 5/8) | 60(2 3/8) | 406(16) | String |

LX216-NB | 4 1/2REG | Near Bit | |||||||

LX311 | 311.15(12 1/4) | 203.2(8) | 6 5/8REG | 6 5/8REG | 71.4 (2 13/16) | 700(27 9/16) | 75(2 61/64) | 406(16) | String |

LX311-NB | Near Bit | ||||||||

LX444.5 | 444.5(17 1/2) | 228.6(9) | 7 5/8REG | 7 5/8REG | 76.2(3) | 700(27 9/16) | 121(4 3/4) | 460(18 7/64) | String |

LX444.5-NB | Near Bit | ||||||||

LX660 | 660.4(26) | 241.3(9 1/2) | 7 5/8REG | 7 5/8REG | 76.2(3) | 762(30) | 121(4 3/4) | 508(20) | String |

KX660-NB | Near Bit | ||||||||

LX914 | 914.4(36) | 241.3(9 1/2) | 7 5/8REG | 7 5/8REG | 76.2(3) | 889(35) | 121(4 3/4) | 610(24) | String |

LX914-NB | Near Bit |

Categories

- Inside Blowout Control Tools

- Subs &Tool Joints

- Downhole Drilling tools

- Swivel joint/Hose loops/Union/valve/oilfield hose

- Cementing fracturing plunger pump and spare parts

- Sucker Rod and Sucker Rod Coupling

- Wellhead Equipment and Tools

- Fishing & Milling Tools

- Oil Country Tubular Goods

- Drilling jars

- Cementing tools and Casing accessaries

- Mud pump spare parts

Contact Us

- +86-17611660323

- info@snpetro-equip.com

- +86-17611660323

- +86-17611660323